FEATURES

- Forged alloy steel used for cylinder & cylinder body

- Single return spring design

- Special quality sealing for specified pressure

- Easy to operate & maintain

- Light weight & compact design

- Unique design of jaw and punch, special steel used for longer life

- Wide range of Power Pack used for user requirement

- Single piece ram & piston design for easy maintenance

- Suitable tool hanger fitted to positioning the tool at any angle for easy to operate

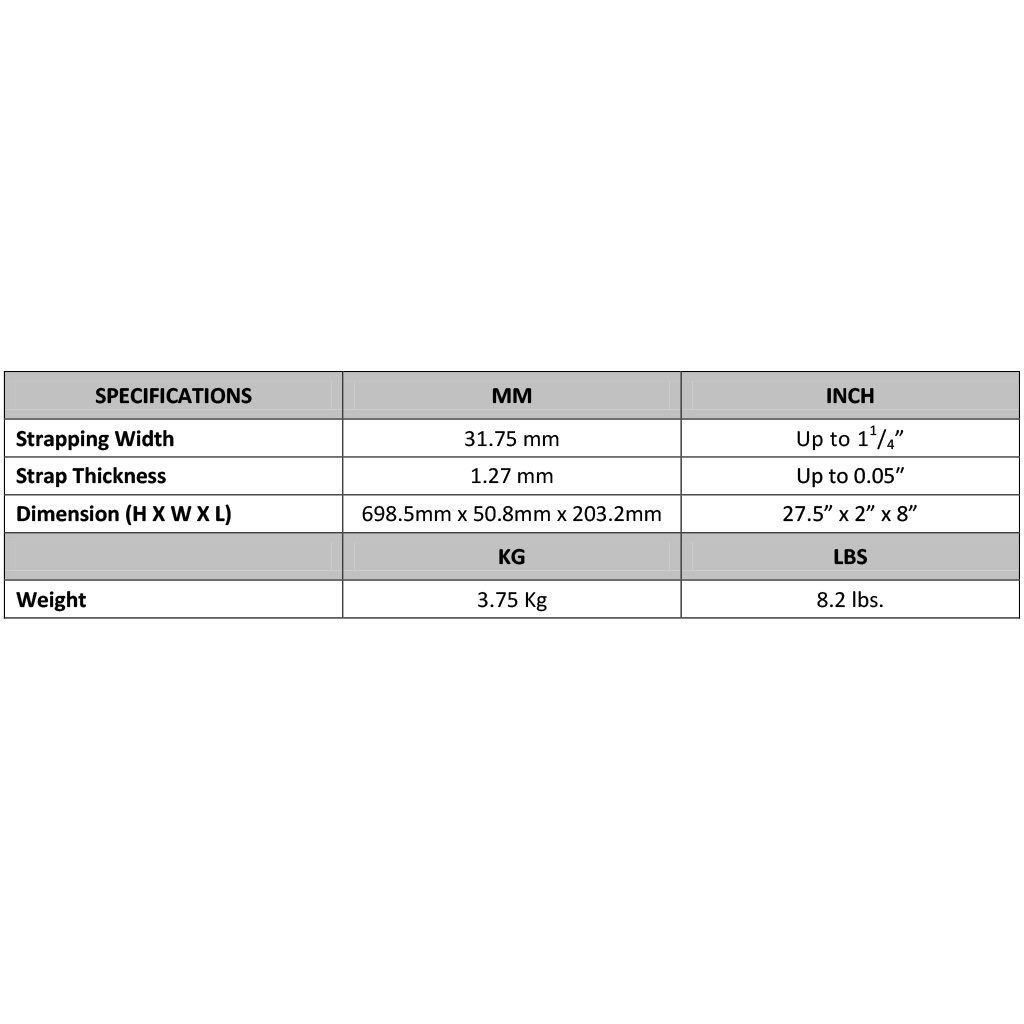

SPECIFICATIONS

| MODEL NO. | CAPACITY | WEIGHT |

| HBS-20 | 20 mm dia | 22 lb /10 kg |

| HBS-30 | 30 mm dia | 39.6 lb/18 kg |

| HBS-40 | 40 mm dia | 52.8 lb/24 kg |

Operation: Operated by hand switch fitted in the handle

Pump: Radial piston pump

Maximum Working Pressure: 315 bar/550 bar

Flow rate of pump: As user requirement

Power Supply Details: 440 volt and 220/110 volt

Power Pack: category “A” or “B” type- can be selected depending on application

PART LIST OF HBS - 20

| PART INDEX | PART NAME | QTY. |

| 1 | HYD. HOSE ADAPTOR | 1 |

| 2 | CYLINDER | 1 |

| 3 | `U` CUP SEAL | 1 |

| 4 | OIL SEAL | 1 |

| 5 | PISTON WITH ROD | 1 |

| 6 | CYLINDRICAL SPRING | 1 |

| 7 | SPACER | 1 |

| 8 | BUSH | 1 |

| 9 | JAW | 1 |

| 10 | HANDLE | 1 |

| 11 | SOC. HD. SCREW-1 | 2 |

| 12 | PUSH SWITCH WITH COVER | 1 |

| 13 | SOC. HD. SCREW-2 | 2 |

| 14 | PUNCH | 2 |

| 15 | MACHINE BODY | 1 |

OPERATIONAL MANUAL

- Check the hose and control cable connectors match with that of the Bar Straightner.

- Attach the hydraulic hose from the power pack to the machine properly so that there can be no leaking of hydraulic fluid.

- Connect the control cable from the power pack solenoid valve to the Bar Straightner.

- Connect the power cable of the power pack to a suitable wall power outlet and switch on the power pack, do not press the switch on the handle of the Bar Straightner right now.

- Let the power pack idle (oil flowing from pump to tank) for a couple of minutes.

- Now place the rod to be straighten between the jaw & punch.

- This is to ensure that the full diameter of the job is within the width of the jaw & punch.

- Hold the job with a gloved hand. Press the trigger & straightning operation start.

- Switch off the power pack and disconnect the power pack from the wall out-let after you finish.

MAINTENANCE

- Keep all the bolts tight and joints oiled at all times.

- Whenever the hydraulic fluid is changed, also change the filter and clean the tank before filling up.

- Never drop the machine which may cause serious damage to it.

SAFETY INSTRUCTIONS

As for any high power cutting machine, the following safety precautions should be strictly maintain during use of this machine:

- Wear safety shoes, gloves and safety goggle during operation.

- Remove oil or grease from your hands, tools and working area.

- Use proper tool as per requirement.

- While the machine is not in use, keep the power pack switched off, so that accidental pressing of trigger cannot cause any injury in case one keeps fingers between the jaw & punch by mistake.

- Check that the balancer and hanging arrangement is strong enough to hold the combined weight of the tool and the job.

0 Reviews

There are no reviews yet.